The fresh produce industry is undergoing a significant transformation as supply chains become increasingly complex and consumer expectations shift. Transparency, authenticity, and efficiency are more important than ever, particularly for products exported to international markets. In response to these challenges, Australian citrus growers, exporters and retailers are harnessing the power of next-generation 2D barcodes to improve traceability, enhance supply chain coordination, and engage directly with their consumers.

Mildura Fruit Company, in collaboration with Citrus Australia, Agriculture Victoria and GS1 Australia, has adopted QR codes powered by GS1 to improve end-to-end visibility within its supply chain. This ensures that each citrus product can be tracked from its origin in Australia to its final destination in export markets such as China and Vietnam.

The challenge

Citrus growers in Australia face several key challenges in guaranteeing product integrity and meeting the increasingly stringent regulatory requirements of importing countries. With counterfeit products becoming a growing concern, brand protection is a top priority. This means that ensuring consumers and retailers can verify the authenticity of Australian citrus products is becoming increasingly critical for maintaining brand trust and safeguarding access to these markets.

In addition, modern consumers are demanding more information about the food they purchase, such as details about its origin, farming practices and sustainability credentials.

Providing this level of transparency is no small feat. It requires innovative solutions that integrate seamlessly into existing supply chains.

Supply chain efficiency is also crucial as improved coordination between growers, packhouses, distributors and retailers is essential for effective food safety and recall management.

Many importing nations, particularly in Asia and North America, have introduced stringent traceability regulations that require comprehensive, real-time data tracking. Failure to comply with these evolving regulatory frameworks could result in restricted market access and reputational damage for exporters.

The solution: QR codes powered by GS1

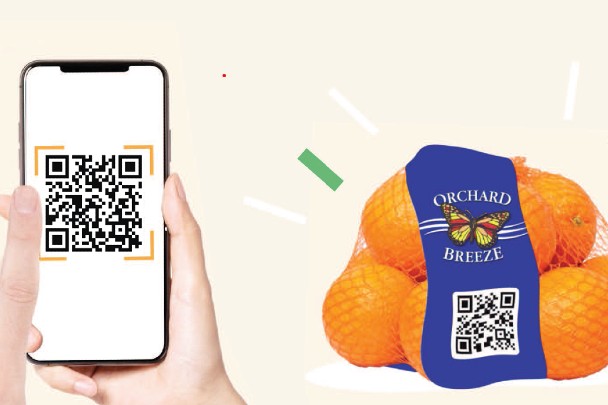

To address these challenges, the Mildura Fruit Company implemented QR codes powered by GS1 on individual citrus packages. This initiative, backed by Citrus Australia and Agriculture Victoria, enables full end-to-end traceability as each product is tracked and authenticated as it moves throughout the supply chain.

Each citrus bag and carton is labelled with a unique QR code powered by the GS1 Digital Link. These QR codes serve multiple functions. For supply chain partners, they enable seamless tracking of each shipment by capturing batch numbers, packing dates and logistics data. This information allows for faster response times in the event of recalls or food safety concerns.

For consumers, scanning the QR code with a smartphone directs them to a multilingual microsite tailored to their location and language preferences. This microsite offers comprehensive product details such as origin information, authentication verification, storage recommendations, and even interactive features such as a feedback mechanism. By incorporating this technology, Mildura Fruit Company has not only strengthened its brand protection efforts, it has also provided a richer and more informative experience for its consumers.

Key results

The pilot project was conducted during the 2022 citrus harvest season, encompassing five different citrus varieties across eleven SKUs. Over the course of six months, more than 580,000 retail bags and 50,000 cartons were labelled with QR codes and tracked through the supply chain. The initiative demonstrated the value QR codes powered by GS1 in real-world conditions, with measurable improvements in both operational efficiency and consumer trust.

Consumers responded positively to the initiative, appreciating the ability to verify product authenticity and access tailored product information in their native language. This proved particularly valuable in markets such as China and Vietnam, where food fraud is a widespread concern. The authentication mechanism helped prevent counterfeit products from reaching consumers, reinforcing the premium reputation of Australian citrus.

From a supply chain perspective, the introduction of QR codes led to improved coordination and faster data-sharing between growers, packhouses, logistics providers and retailers.

By integrating GS1 standards with existing data infrastructure, the company was able to streamline its traceability efforts without disrupting established workflows. The ability to track individual shipments with precision reduced the time required to identify and isolate potentially compromised products, enhancing overall food safety.

Beyond operational benefits, the initiative also provided valuable consumer insights. The microsite enabled a two-way flow of information, allowing consumers to provide feedback and express their preferences. This data helped Mildura Fruit Company refine its marketing strategies and tailor its product offerings to meet the evolving demands of different markets.

Key learnings

Following the success of this initiative, the project team identified several key learnings that could guide future traceability implementations. One of the most important takeaways was the need to act early. As regulations surrounding food traceability continue to tighten, businesses that proactively adopt digital solutions will be better positioned to maintain compliance and secure long-term market access.

Defining the scope of a traceability project from the outset is also crucial. For businesses looking to implement similar solutions, starting with a clearly defined pilot phase allows for gradual scaling while minimising disruption. Collaboration across the supply chain is another critical factor in achieving success a working closely with logistics providers, wholesalers and retailers ensures that traceability efforts are effective and widely adopted.

Looking ahead, the industry is exploring further advancements in traceability technology.

The integration of QR codes powered by GS1 with transport and logistics systems presents further opportunities to create a more seamless end-to-end tracking experience.

Additional innovations, such as virtual pallet packing interfaces, could further enhance visibility at the wholesale level.

With increasing regulatory scrutiny on food traceability, adopting GS1 standards should be a key focus for any businesses looking to future-proof their supply chains.