Method 1

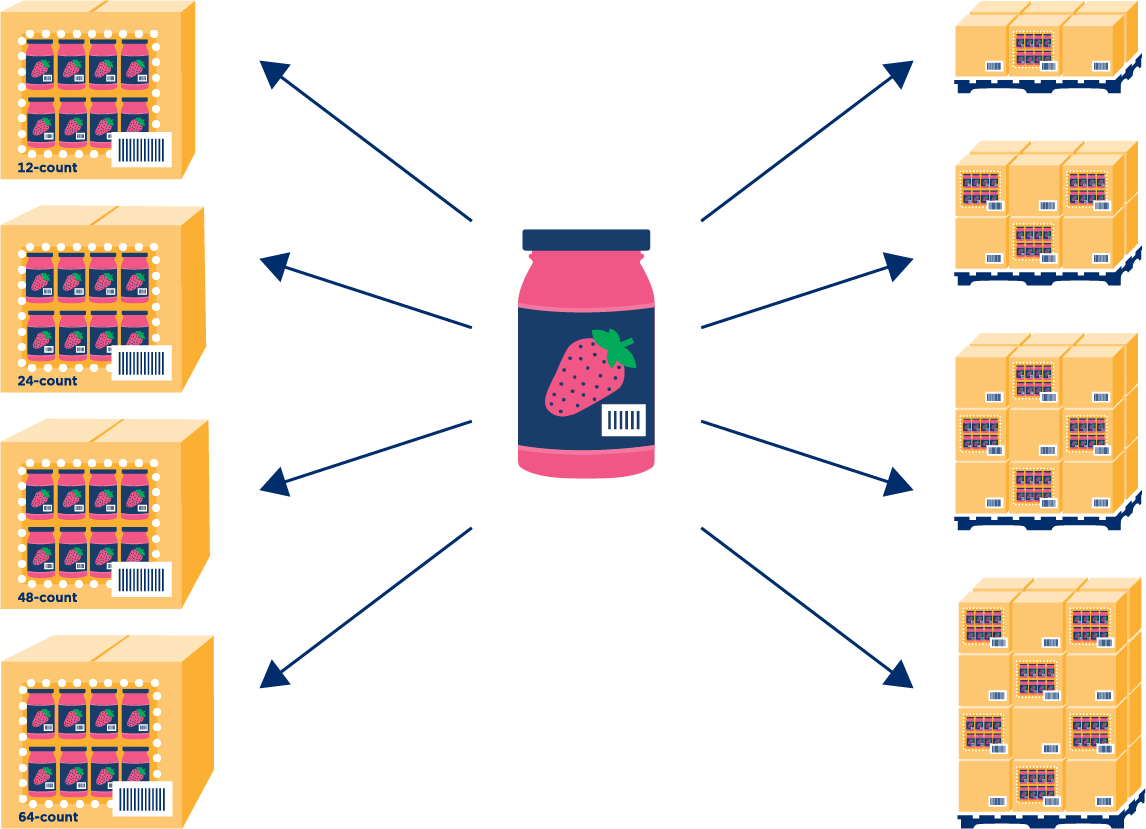

One option is is to assign different GTIN-13s at every packaging level.

Remember, when capturing a GTIN-13 in a GS1-128 or ITF-14 barcode, you’ll need to include a leading zero as GTIN is a 14-digit field in these barcodes.

| GTIN-8 | 0 | 0 | 0 | 0 | 0 | 0 | N | N | N | N | N | N | N | N |

| GTIN-12 | 0 | 0 | N | N | N | N | N | N | N | N | N | N | N | N |

| GTIN-13 | 0 | N | N | N | N | N | N | N | N | N | N | N | N | N |

| GTIN-14 | N | N | N | N | N | N | N | N | N | N | N | N | N | N |

If the product is to be supplied into retail, a GTIN-13 must be assigned to the retail pack and captured in an EAN-13 barcode.

Method 2

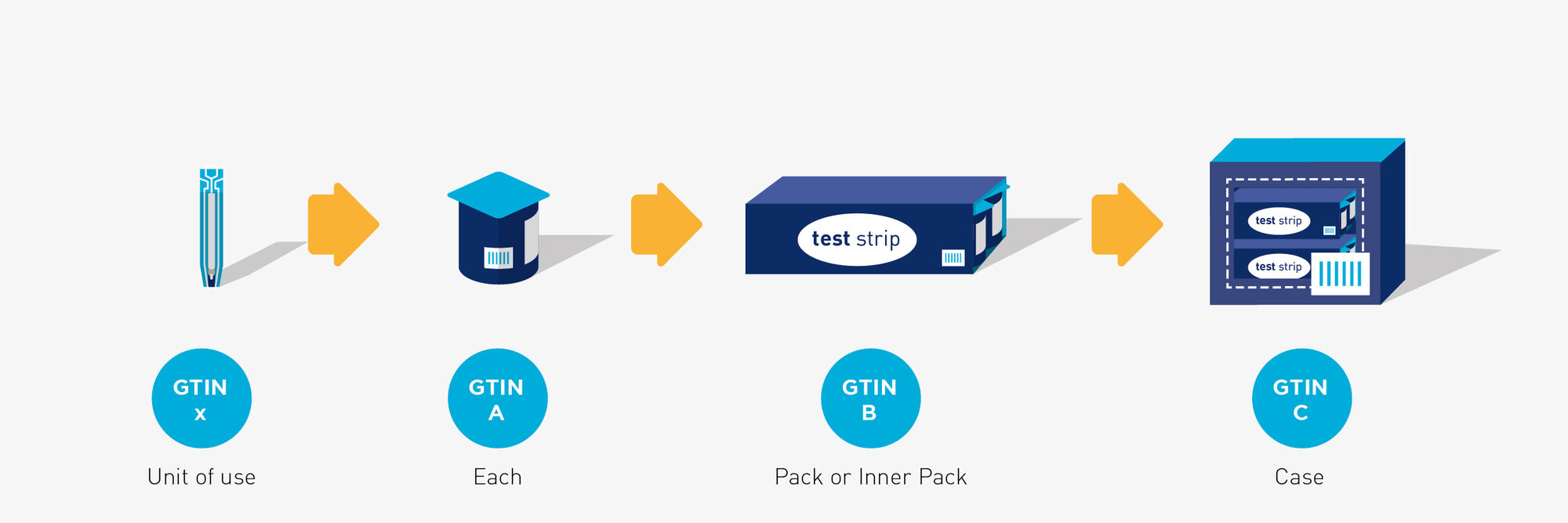

Alternatively, you can create GTIN-14s .

Start by assigning a GTIN-13 for the each or consumer unit, then allocate GTIN-14s created from that GTIN-13 to each additional packaging level.

In the illustration below GTIN A would be the GTIN-13, and GTINs B, C and X would be allocated GTIN-14s:

Using this method would mean that an organisation would not go through their allocation of GTIN-13s as quickly.

Common mistake

Some organisations are under the impression that in order to meet regulatory requirements they have to use GTIN-14s to identify their different packaging levels. This is incorrect – the method chosen is completely up to the GTIN allocator.